Sound insulation in accordance with regulations

Smoke-free rescue and escape routes

Heat-resistant and flexible partitions

Preventative building protection due to the prevention of smoke spreading

Noise reduction due to sound absorber

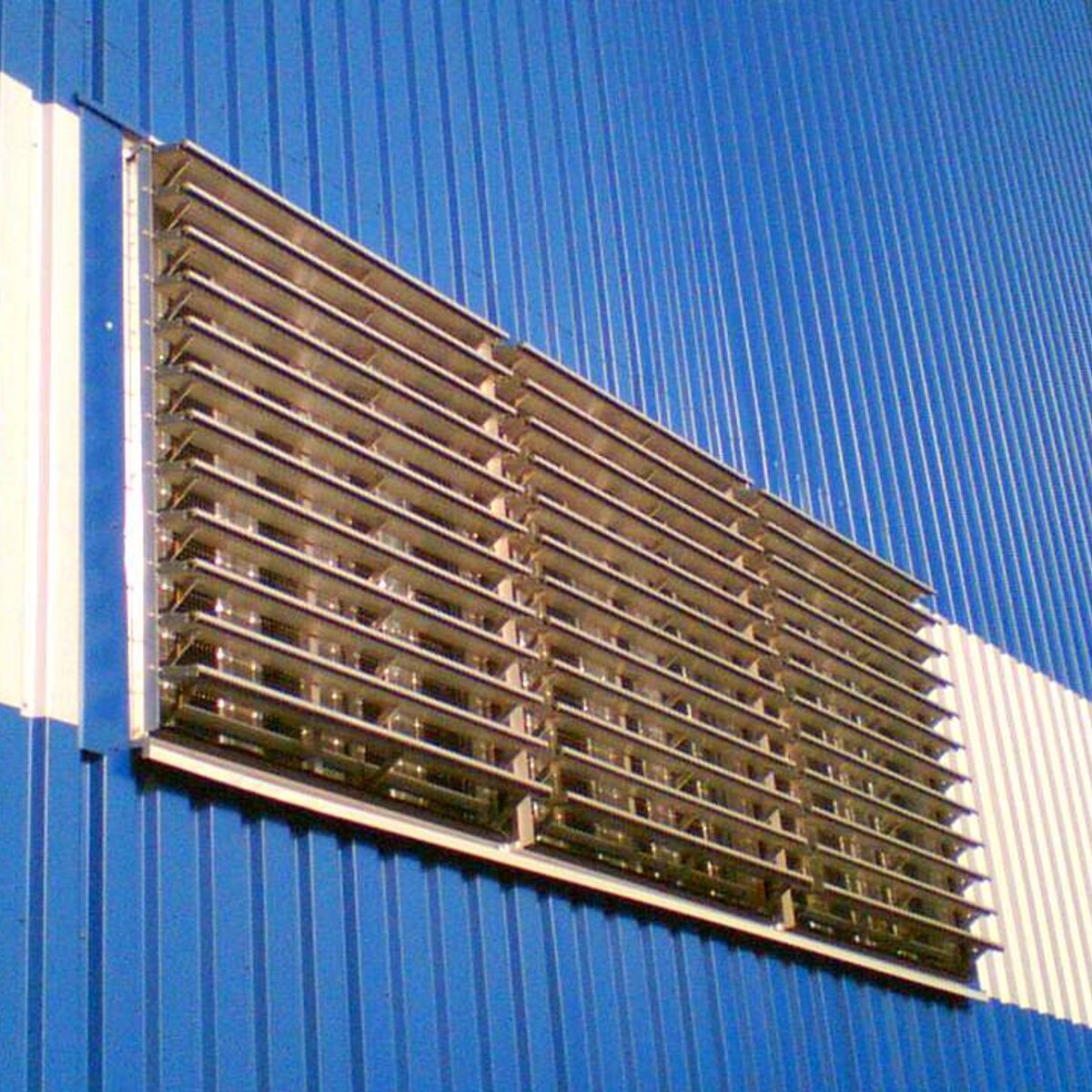

Noise reduction measures that prevent noise emissions from escaping are frequently necessary for natural ventilation in noise intensive operations and systems. The use of sound traps has been shown to be an effective solution. Calculations will be performed by sound experts to ensure that the levels of noise in an inhabited area are complied with. Based on these regulations, the necessary sound reduction and the permitted pressure loss will be investigated in the factory and the number of devices, size and level of performance will be determined. In connection with the natural air supply and exhaust systems, energy-free aeration and ventilation is possible without the noises from the interior of the building getting outside. Technical design including the connection to the building structure is performed during the INDU LIGHT factory planning.

Long-lasting products with an optimised flow design

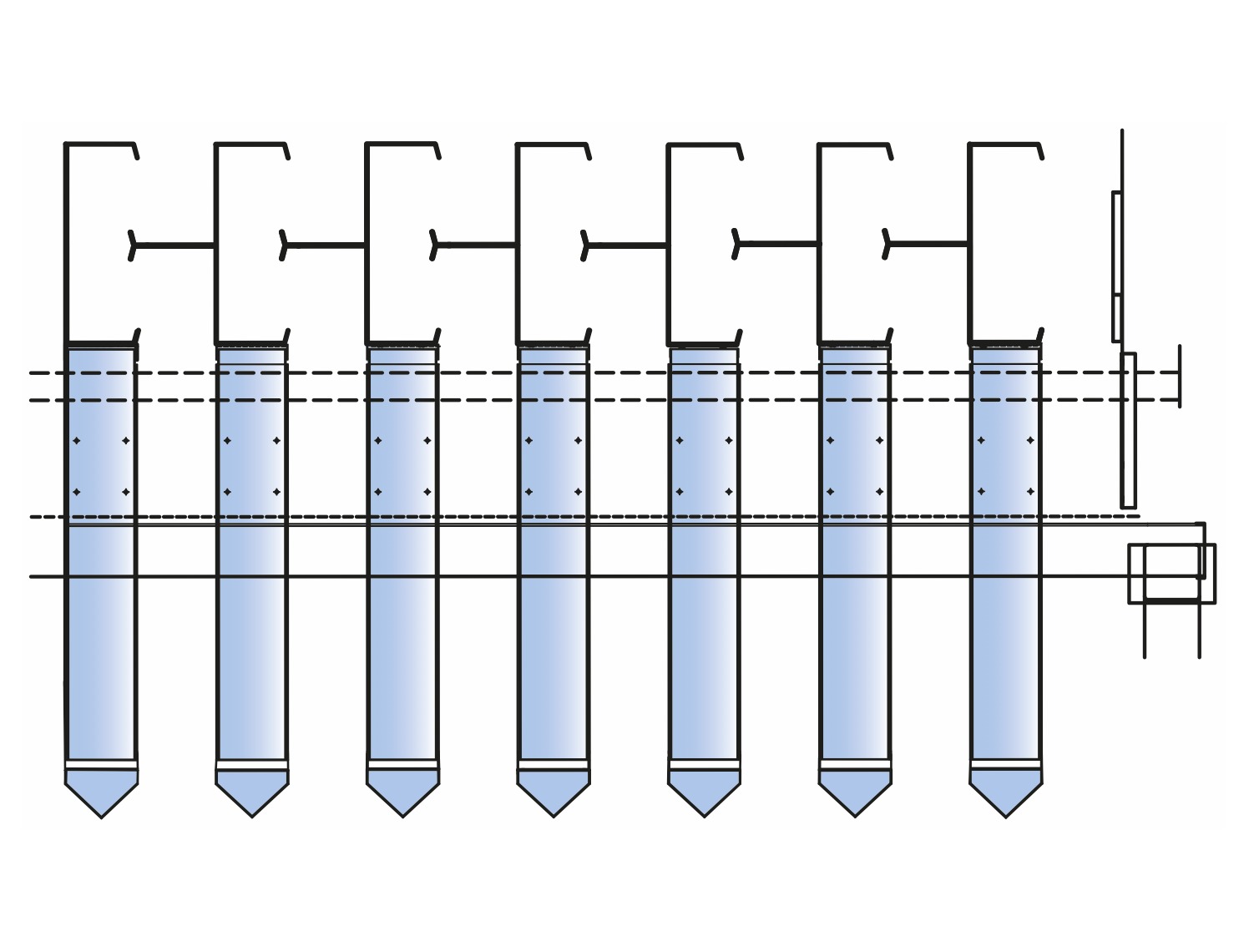

The profiled silencer housing made from torsion-resistant galvanised steel plate is the support for the sound traps. To achieve the level of sound absorption needed, the housing will be equipped with sound traps with different properties.

Sound traps have a flow-optimised radius. The absorption material of moisture-repellent and corrosion-proof rock wool (building material class A1 in accordance with DIN 4102) as a filling with a tear-proof and abrasion-proof surface made of glass silk laminated on both sides is abrasion-proof up to a wind speed of 20 m/s. The maximum operating temperature is 100°C. In the event of heavy dirt contamination, the robust perforated sheet metal design can be used as an alternative.

Continuous usage without outgoing operating costs

As a supplement to the INDU LIGHT ventilation system, silencers will be attached directly to the ventilation device within the building. The effect occurs immediately and can be used continuously without resulting in additional operating costs. In the event of very heavy soiling, we recommend that the perforated plates are cleaned occasionally.